HOME

AUTOMATIC mini

FIRE EXTINGUISHERS

AMFE.pro

For households, medicine, military, marine and other industries

AUTOMATIC mini

FIRE EXTINGUISHERS

AMFE.pro

Minimal effort – maximum safety for people and electrical equipment

APPLICATION

All the electrical devices pose a constant elevated fire risk. That is why automatic fire extinguishers were created to protect from fire in diverse environments:

Industry and automotive sector

Airports, rail, marine

Hospitals and laboratories

Museums and households

IT, telecommunication industry and others

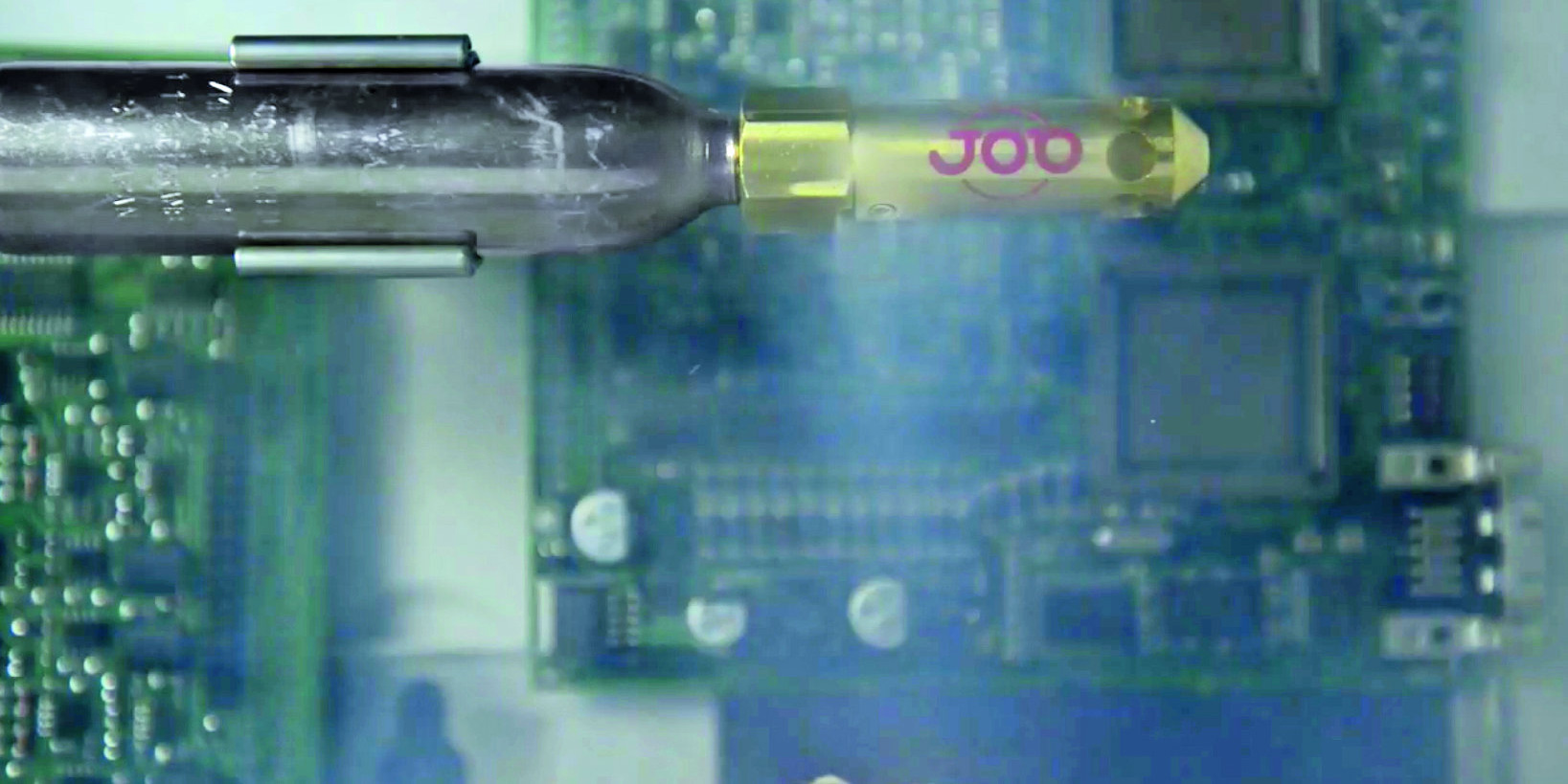

HOW DOES IT WORK

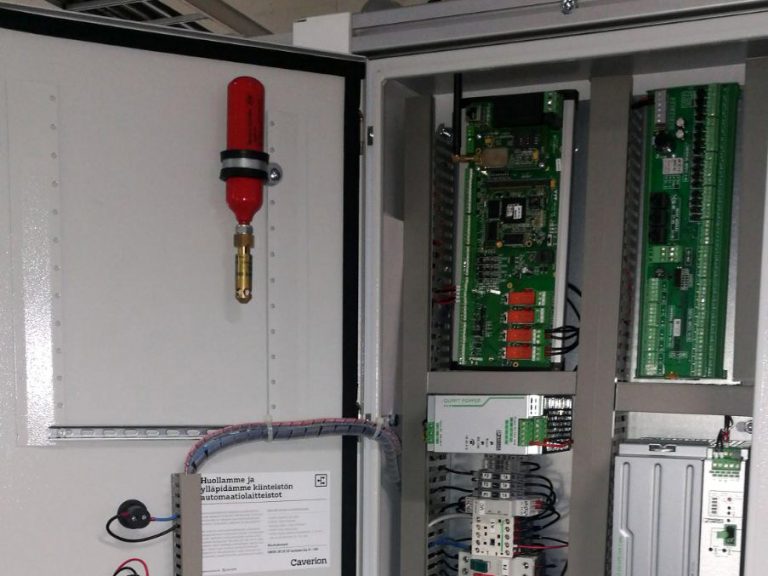

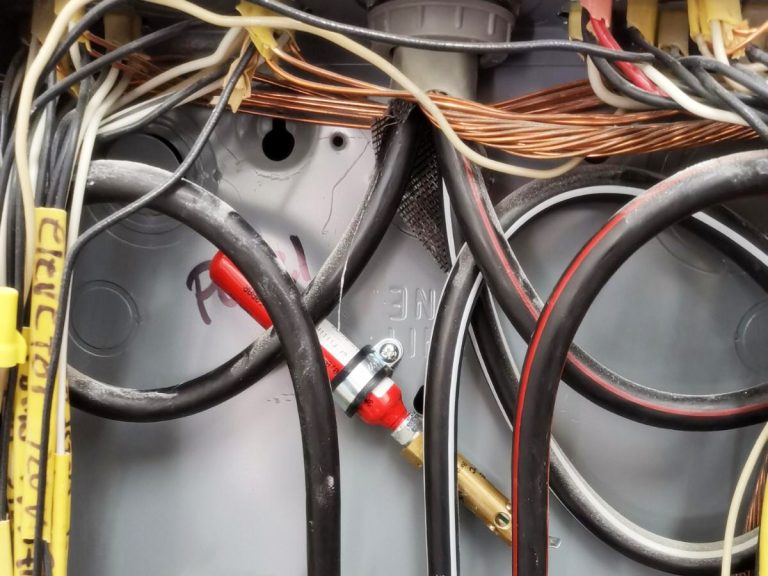

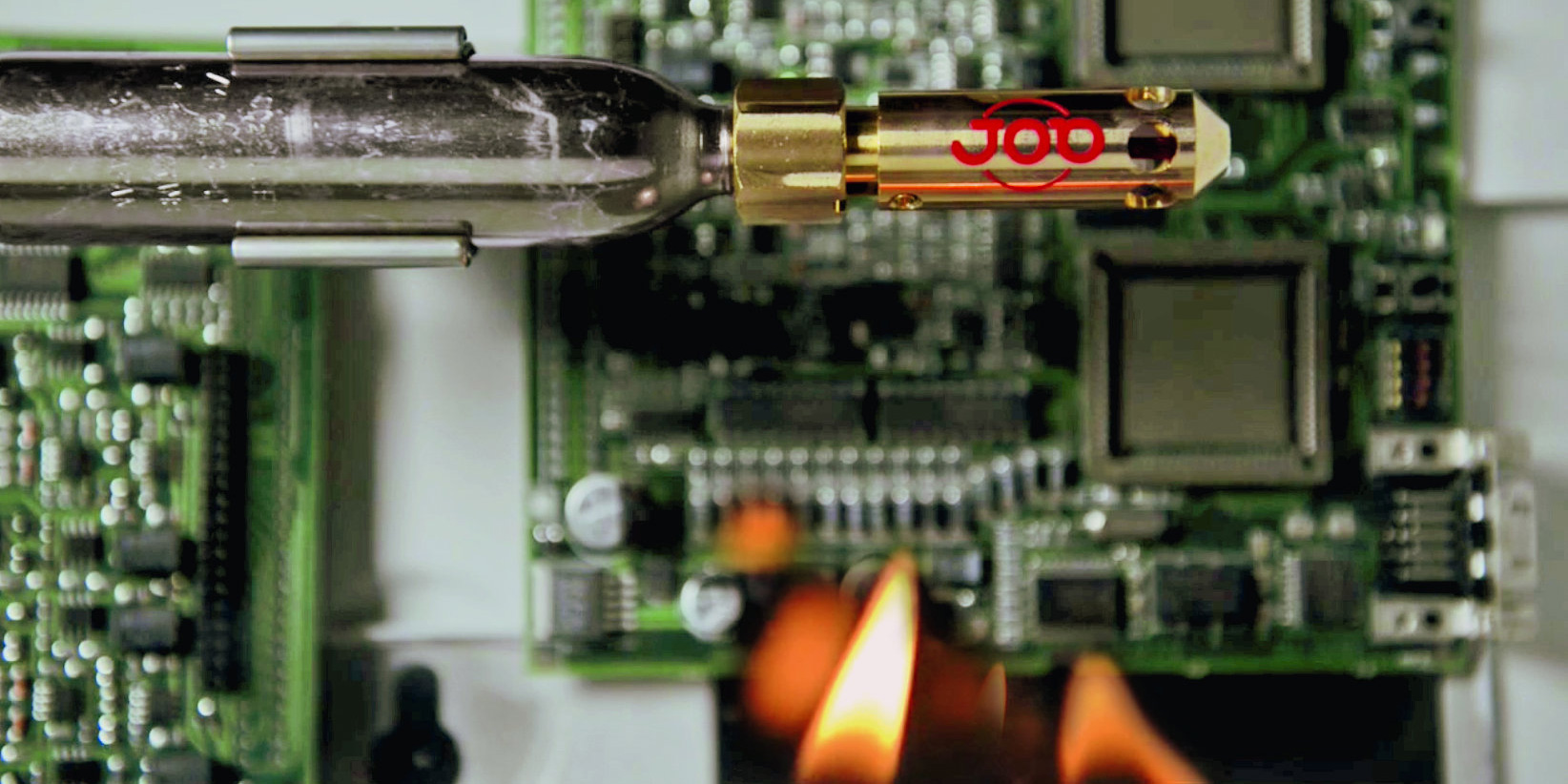

Mini fire extinguishers automatically detect and extinguish a fire inside electrical devices, preventing the further spread of a fire.

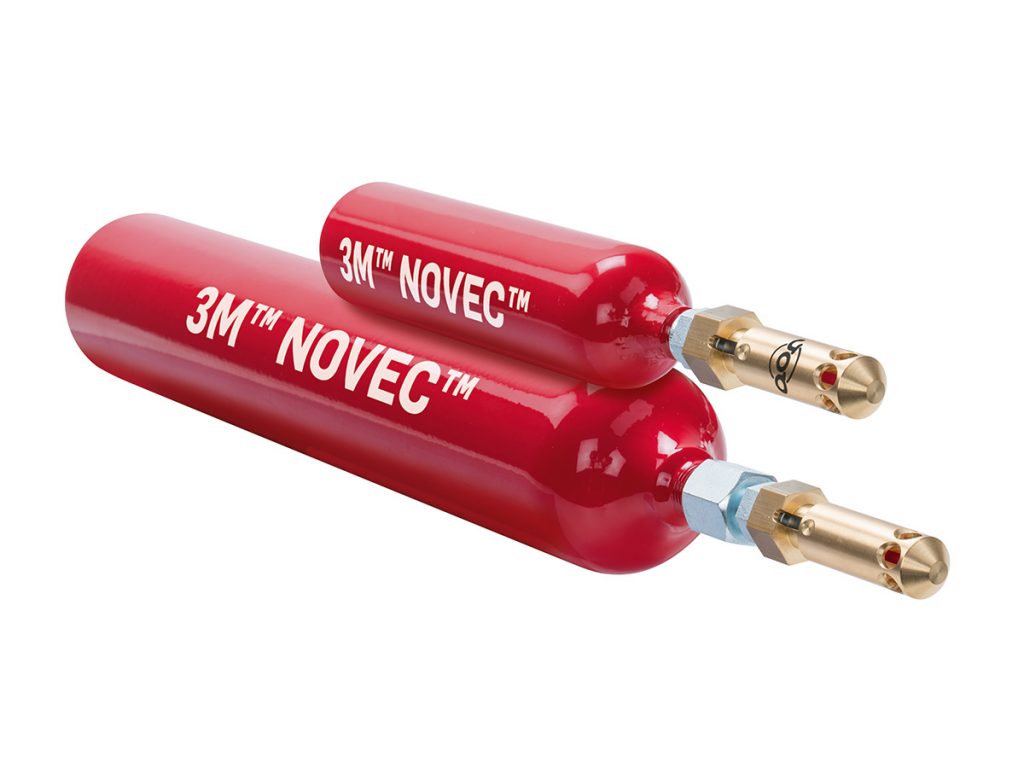

After the predetermined operating temperature of the heat-sensitive glass bulb is reached, the glass bulb bursts into small fragments and triggers a mechanism that releases from the cylinder the new generation fire extinguishing agent 3M™ Novec™. The fire is extinguished in an early stage thus keeping the damages as small as possible.

WHY CHOOSE AMFE

Easy to use and easy to install

Maintenance-free

No electric power supply required

No hazard to health, environment, equipment

Rapid fire extinguishing, no water being used

Variety of temperatures available

Small investment, high safety

ADDITIONAL AMFE MODELS

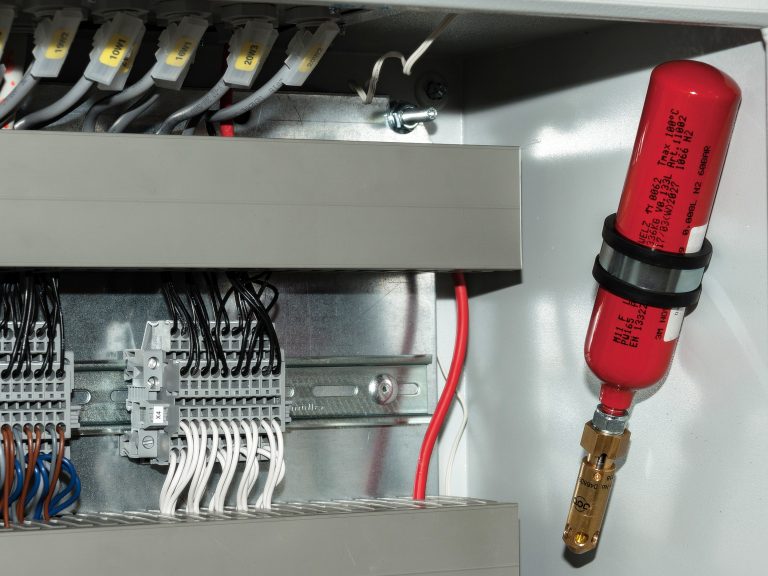

S-AMFE – SENDS A SIGNAL

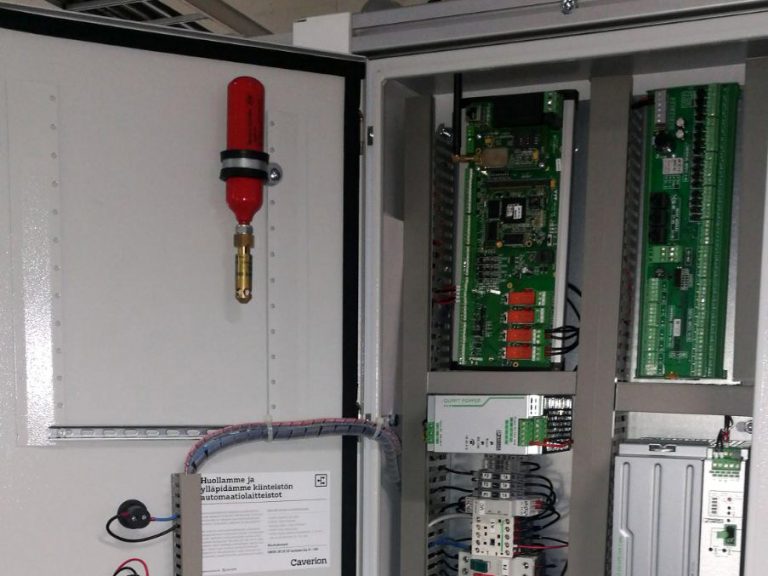

The S-AMFE not only releases the extinguishing gas, but also signals that it has. In installations where accessibility is limited, the S-AMFE can be connected to a monitoring system by two connectors for reading a signal.

Permanently controlling if the S-AMFE has been initiated (e.g. line control through a PLC or monitoring device) allows for precise knowledge about the status of whether and where a fire might have started in an otherwise hard to reach installation.

The S-AMFE is rated for typical PLC signals of 24V/48V and 1000mA. The connectors are standardized (6,3mm blade terminals), but customizations are possible.

R-AMFE – CAN BE TRIGGERED REMOTELY

The R-AMFE works like a conventional AMFE, releasing the extinguishing gas, when the thermobulb bursts after the activation temperature has been reached. Additionally, the R-AMFE can be remotely triggered by activating a current signal into the R-AMFE, causing a fast and precise increase of the heat at the bulb, ultimately resulting in a burst of the thermobulb assembled and release of the extinguishing gas.

R-AMFE can also work much faster than a traditional AMFE if controlled by a monitoring device which also reads e.g. smoke detector signals and, upon the early detection of smoke, initiates the signal to release the R-AMFE even before significant enough heat buildup. The applied current defines the time until the R-AMFE is initiated.

As application requirements for the R-AMFE are customer specific, consulting the representatives of AMFE.pro is required to define electrical and mechanical details to guaranty reliable and sufficient operation.

THE CHALLENGE

Washing machines, televisions or industrial power supplies – fires in technical devices are a continuously increasing serious threat. And not only at homes damages caused by fires are increasing. There is also a significant risk of fire in the industry and automotive sector. Another example are highly valued collections which are subject to persistent fire hazard.

The challenge is to automatically, energy-supply independently, detect and extinguishing fires already in the early stage, consequently providing more safety. A system is needed, that can extinguish these fires reliably, fast and easily at any time and without external resources inside a housing.

THE FUNCTION

Due to rising heat in a fire scenario, increases the pressure inside the glass bulb of the AMFE.pro fire extinguisher. After the predetermined operating temperature of the heat-sensitive glass bulb is reached, the glass bulb bursts into small fragments and triggers a mechanism that releases the gas from the cylinder.

The extinguishing medium is released through the holes in the outlet body and extinguishes the fire when the fire is still in an early stage.

The quick operation and the effective extinguishing of the fire prevents further expansion of the fire and helps keeping damage small.

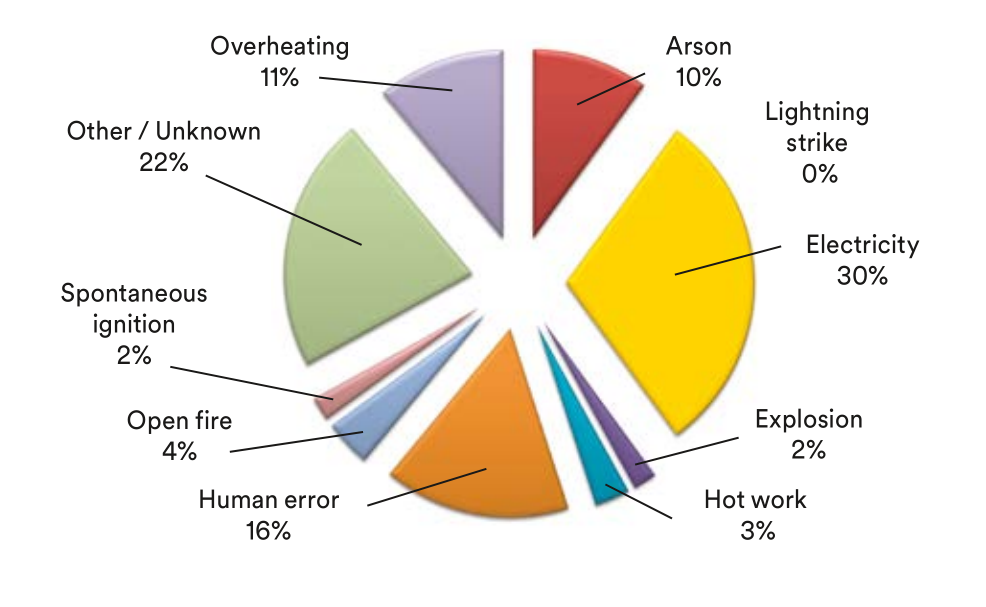

FIRE STATISTICS*

** The number of registered fires in the Baltic countries is relatively small, corresponding with the number of the total population. However, the average number of fires per 1000 inhabitants in the Baltic countries would be larger than, for instance, in Finland or Russia.

* Data from CTIF World Fire Statistics Center. Readers should use caution in interpreting these results and be aware that every country has its own methods of data collection and analysis of fires, fire deaths and fire injuries.

THE FIRE TRIANGLE

A fire requires 3 elements:

Oxygen

Fuel

Heat

A fire naturally occurs when these elements are combined in the right mixture. In the

presence of a fuel and oxygen, a sufficient amount of heat would be enough to ignite a fire. These elements must be neutralized to stop the fire.

The extinguishing medium 3M™ Novec™ used in AMFE products withdraws the heat from the fire, thus interrupting the chain reaction of the fire.

CAUSES OF FIRES

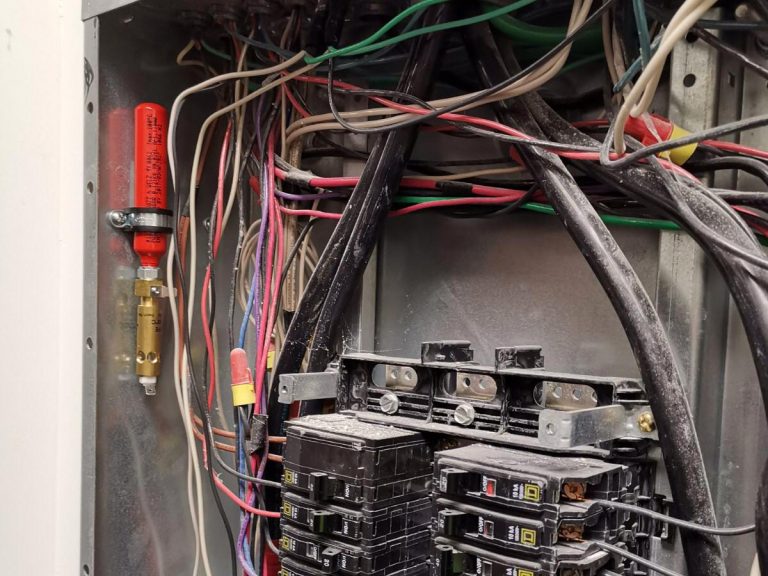

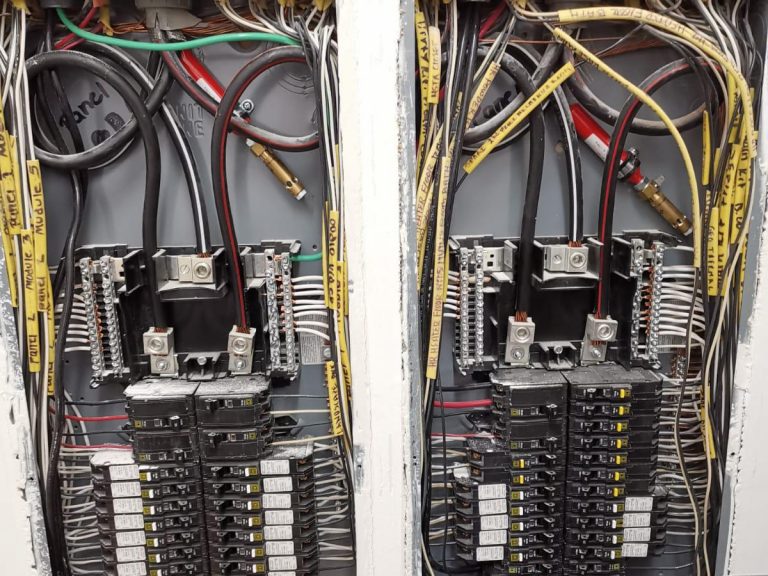

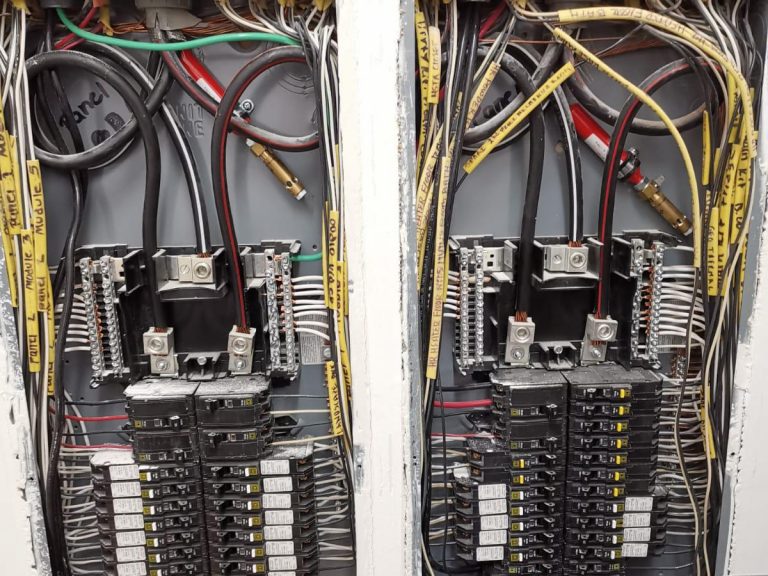

ELECTRICAL EQUIPMENT POSES A CONSTANT FIRE RISK

Whether at home or in the office, in industrial plants, laboratories, hospitals or doctors’ practices: electrical equipment and appliances can be found pretty much everywhere. These devices are permanently supplied with power, which means they pose an elevated fire risk.

In many cases, the areas where electrical equipment is used are either unprotected or provide only insufficient protection against fire risks. Think about your home, for example. Smoke detectors or hand-held extinguishers are useless here if nobody is at home.

Automatic AMFE.pro fire extinguishers, integrated into electrical devices, can provide a direct protection from fire risks in diverse environments.

PROTECTION IN HOUSEHOLDS AND OFFICES, MEDICINE AND INDUSTRY

KEY SECTORS USING AMFE

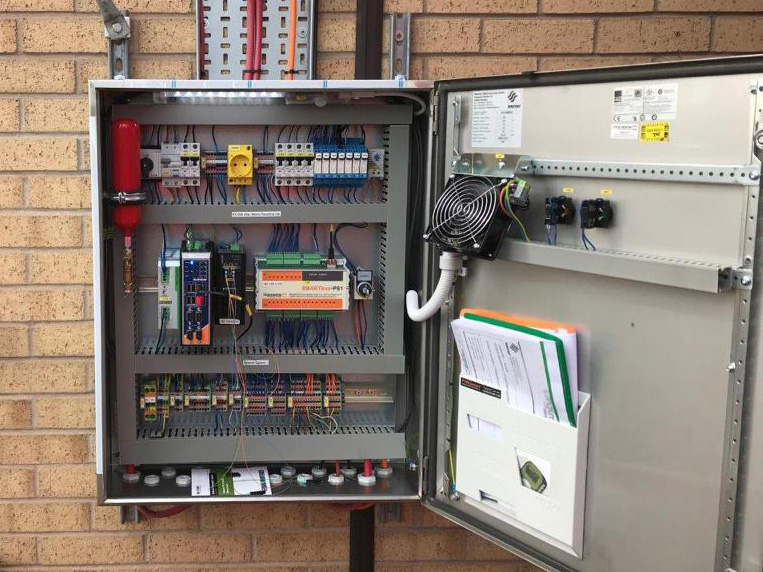

Automatic mini fire extinguishers provide a reliable fire protection not only in the households and offices but also in the industry, medicine and other sectors. Examples of the diverse application:

Industry, automotive, rail

IT areas, offices, data centers, control stations (e.g. at airports)

Hospitals, medical centers, laboratories, CT and MRI rooms

Marine - machinery spaces and pump rooms, communication and control centers

Archives, libraries and museums with valuable collections and exhibits

Telecommunication - telephone exchanges, technology locations

Households with domestic appliances and objects of value

Power stations, substation rooms, control stations

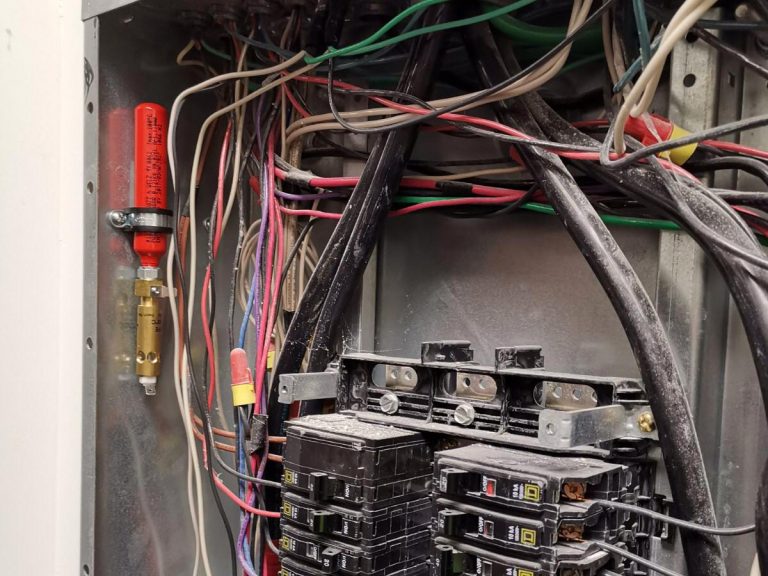

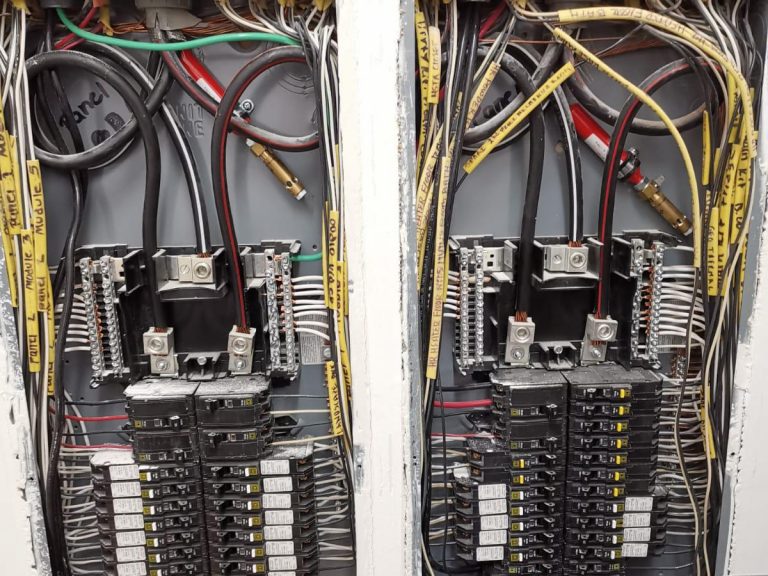

OTHER EXAMPLES OF AMFE PRODUCT APPLICATION

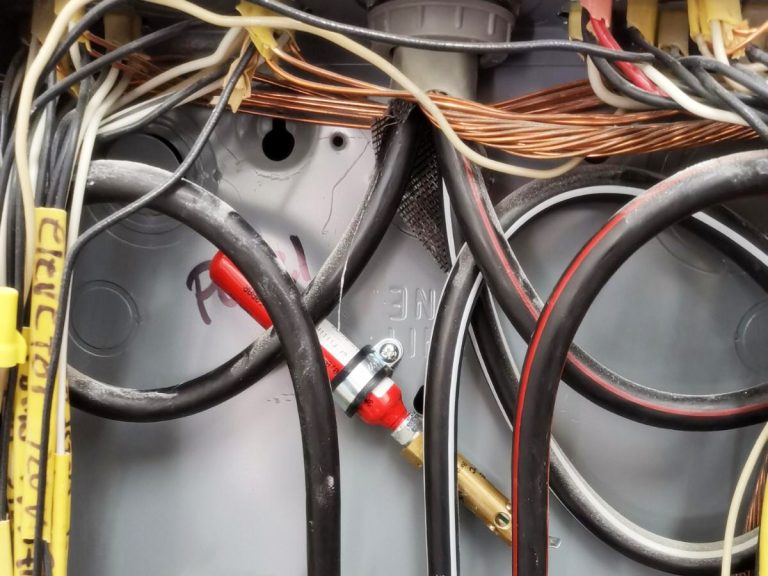

AMFE products are not intended for the protection of an entire room. AMFE shall be used to protect small enclosed equipment, cabinets and appliances of any kind:

Production equipment (e.g. small machines)

Computers, computer racks, small electrical cabinets

Valuable exhibits (e.g. at museums or personal)

Machines, industrial appliances, conduit boxes / power distribution panels

Infrastructure objects, aerospace and military objects

ATMs, vending machines (e.g. in halls and evacuation paths)

Deposit and mailboxes at commercial buildings (e.g. in banks against vandalism)

Leisure marine vessels (e.g. engine compartment, fuse and connection boxes)

THE ADVANTAGES OF AUTOMATIC MINI FIRE EXTINGUISHERS

Easy to use and easy to install (retrofittable and scalable)

Robust and shock tolerant, maintenance-free

No hazard to human health, environment, equipment, materials

Rapid fire extinguishing, no water being used

3M™ Novec™ fire extinguishing agent (CO2 also available)

Release mechanism qualified in the automotive and sprinkler industry

Variety of operating and releasing temperatures available

Mechanical release - no electric power supply required

Small size available - can be built into small cabinets

Small investment, high safety for people and equipment

DEVELOPED FOR THE FUTURE:

3M™ NOVEC™ ENGINEERED FLUIDS ARE SETTING A NEW STANDARD

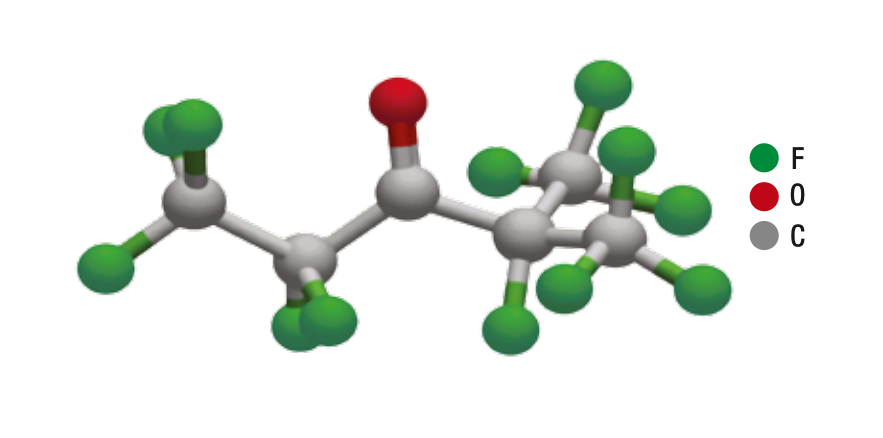

3M™ NOVEC™

This specific 3M™ Novec™ Engineered Fluid is a C6–fluoroketone with the chemical formula CF3CF2C(O)CF(CF3)2. At room temperature it is a liquid. It has a boiling point of 49°C. When discharged, 3M™ Novec™ Engineered Fluid rapidly vaporizes from a liquid to a gas.

Novec Engineered Fluids are a new generation of products, developed by 3M as a replacement for conventional solvents, heat transfer media, fire extinguishing agents, and for a wide range of other applications.

It ensures maximum fire protection for people as well as protection for your electrical equipment, systems and valuable assets, as these remain undamaged by the extinguishing agent.

CHEMICAL FORMULA

SECURE LONG-TERM INVESTMENT + SAFE FOR THE ENVIRONMENT

3M™ Novec™ 1230 Fire Protection Fluid for AMFE systems ensures long-term investment security, even in large-scale installations, because this agent has the lowest global warming potential (GWP) and ozone depletion potential (ODP) of all hydrocarbon alternatives.

AMFE is MPA and VDE tested and REACH compliant.

Used as an extinguishing agent, Novec Engineered Fluid helps to future-proof your fire protection system. It is classified as non-hazardous and not only meets today’s regulations but also those of the foreseeable future.

HIGH SAFETY FOR PEOPLE

Typically, fire extinguishing agents pose a potential hazard to human health. The hazardous effect of an agent after its discharge is evident from its approved use concentration. The NOAEL scale (No Observed Adverse Effect Level) is the internationally accepted limit for the various extinguishing media.

The safety margin for people is calculated on the basis of the difference between the use concentration and the specific NOAEL value. The use concentration is the amount of extinguishing agent required to safely extinguish the fire.

The AMFE uses amounts of the extinguishing agent small enough that this aspect can be safely ignored. As the graphic shows, Novec 1230 Fire Protection Fluid provides by far the highest safety margin when used in large-scale stationary fire extinguishing systems. This level of safety is maintained, even in the case of subsequent modifications made within the protected area (e.g. the integration of additional inventory, whereby the room’s oxygen content is lowered and the safety margin reduced).

THE SAFEST EXTINGUISHING AGENT FOR OCCUPIED SPACES

NOVEC™ - IDEAL FOR USE IN SPECIAL HAZARD AREAS WHERE MAINTAINING CONTINUOUS OPERATION OF HIGH-VALUE EQUIPMENT IS CRITICAL BOTH DURING AND AFTER THE OUTBREAK AND SUPPRESSION OF A FIRE

VERY SHORT EXTINGUISHING TIMES

Once the AMFE is activated, the device is rapidly flooded with 3M™ Novec™ Fire Protection Fluid. Depending on the size of the cylinder, it takes approximately just 10 seconds to reach the required concentration level of extinguishing agent. At this point, the full extinguishing effect is already achieved.

The extinguishing medium withdraws the heat from the fire, thus interrupting the chain reaction of the fire. In just a few seconds, the fire within the device is extinguished.

An AMFE system with Novec™ Engineered Fluid extinguishes fires much faster than an AMFE with inert gas or CO2. The damage to high-value equipment and machines caused by the rapid spreading of fire can thus be significantly reduced.

The comparison of the performance of stationary fire suppression systems illustrates the extinguishing performance of various agents.

TIME ADVANTAGE: FIRE SUPRESSION SYSTEM WITH NOVEC 1230

THE ADVANTAGES OF NOVEC™

Highly efficient, only small quantities are required

Rapid extinguishing

No hazard to human health

No damage to equipment and materials

Electrically non-conductive and no corrosive effects

Leaves no residue to clean up

Minimizing consequential damage

Lowest global warming potential (GWP=1)

Zero ozone depletion potential

HOW DOES NOVEC™ FUNCTION

The extinguishing agent NOVEC™ is heavier than air. A higher position in a protected enclosure will improve the extinguishing effectiveness and speed of how fast a fire is detected and extinguished.

After being discharged by the automatic mini fire extinguisher, NOVEC™ gasifies immediately to flood the area as a gaseous agent. Novec Fire Protection Fluid has an excellent penetration capacity and rapidly reaches all critical areas (e.g. in switching cabinets).

Unlike inert gases, the extinguishing effect of Novec Fire Protection Fluid is not based on oxygen displacement, but on the principle of homogenous inhibition (which means there is no hazard to human life from a shortage of oxygen).

When the extinguishing agent comes into contact with the source of the fire, it removes heat energy and reduces the temperature to the point that the chain reaction is interrupted.

TECHNICAL SPECIFICATION

SIZING OF THE AMFE

For calculation of the required amount of extinguishing agent all applicable standarts and norms shall be considered. Standards which could typically be applied for sizing the extinguishing agent amount needed include:

NFPA 12

NFPA 2001

VdS 2093

VdS 2381

EN 15004

ISO 14520

CONFIGURATION

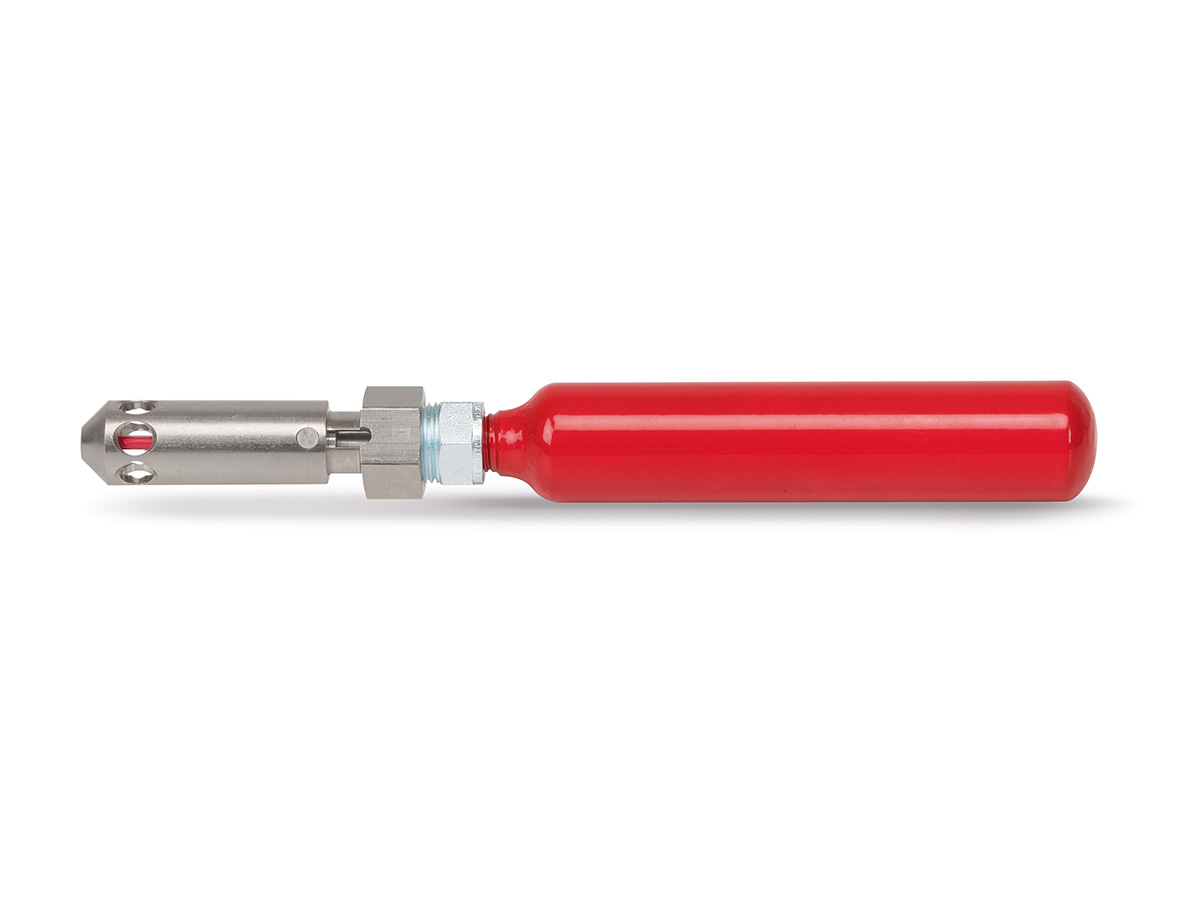

Dimensions (without cylinder): ø 16 mm x 62 mm / 0,63“ x 2,52“

Minimum installation depth: 20 mm / 0,79“ (w/o cylinders)

Activating temperature: 57°C – 260°C / 134,6° F - 500° F

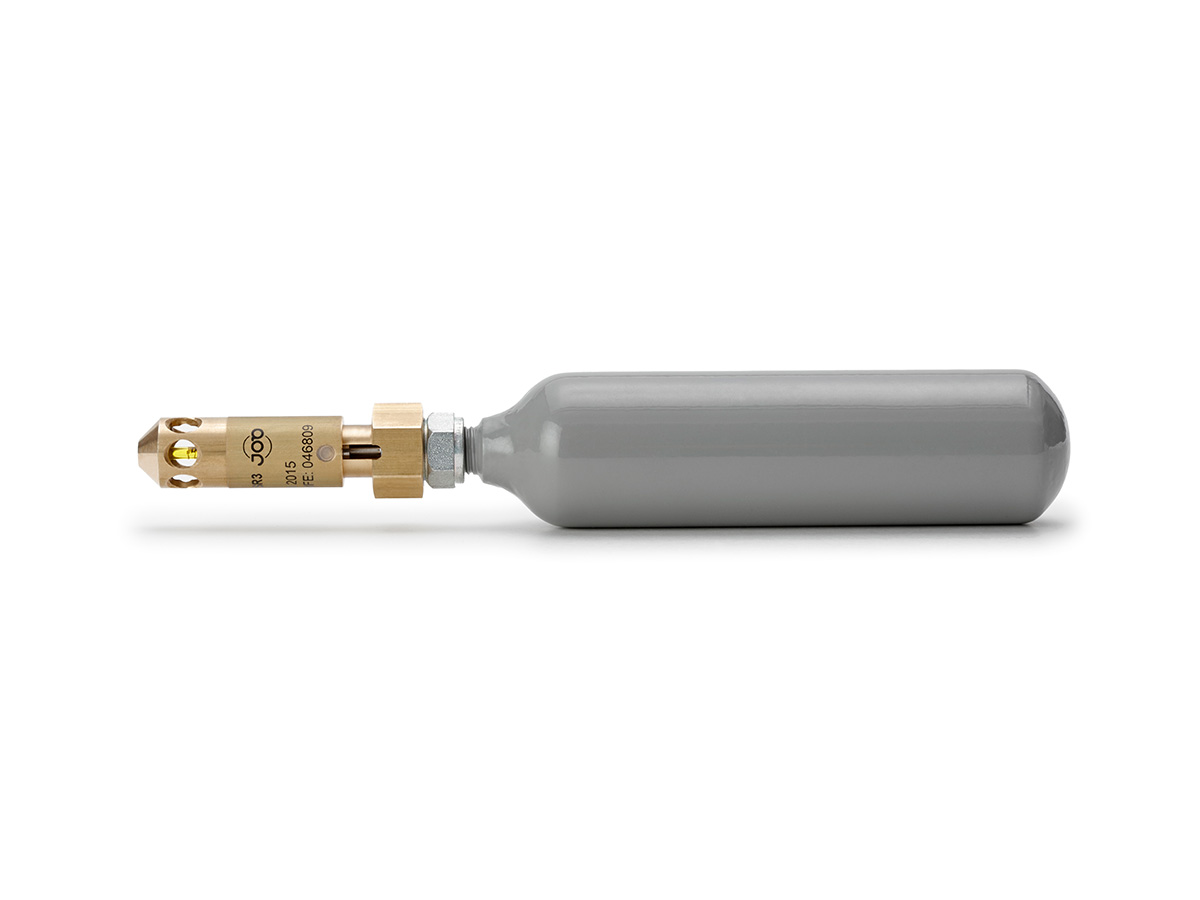

Extinguishing agents: 3M™ Novec™, CO2

Lifetime: 9 years + (for the cylinders)

Maintenance free

Lifetime: ∞ for release mechanism

(see manual for details)

3M NOVEC as fire extinguishing agent | CO2 as fire extinguishing agent | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Physical dimensions of the cylinder | Mounting brackets | NOVEC content | Protected volume [m³]* with NOVEC | |||||||

Size | Size Diameter x length [mm] | Size Diameter x length [inch] | Volume [liter] | Volume [floz] | Recommended brackets [DIN 3016-1]

| NOVEC volume [ml] | Class A[E] fire (4,2% NFPA 2001) | Class B fire (5,9% NFPA 2001) | CO2 weight [kg] | Protected free volume [m³]** with CO2 (NFPA 12, class A fire)

|

#0 | 22×128 | ⅞ x 5.04 | 0,026 | 0,81 | RGSS 22 | 24 | 0,06 | 0,04 | n. a. | n. a. |

#1 | 35×154 | 1⅜ x 6.06 | 0,080 | 2,70 | RGSS 35 | 72 | 0,19 | 0,14 | 0,035 | 0,037 |

#2 | 40×186 | 19⁄16 x 7.32 | 0,133 | 4,50 | RGSS 40 | 120 | 0,32 | 0,23 | 0,060 | 0,075 |

#3 | 51×251 | 2 x 9.88 | 0,267 | 9,00 | 2x RSGU 56 | 241 | 0,64 | 0,46 | 0,135 | 0,084 |

#4 | 51×356 | 2 x 14.02 | 0,400 | 13,50 | 2x RSGU 56 | 360 | 0,96 | 0,69 | 0,200 | 0,124 |

#5 | 60×380 | 23⁄8 x 14.96 | 0,670 | 22,60 | 2x RSGU 63 | 603 | 1,61 | 1,15 | 0,350 | 0,217 |

* Protected volumes are estimates. NFPA2001 (2012) standard formulas have been applied. The manufacturer is not responsible for sizing. The actual sizing is the responsibility of the customer.

** Protected volumes are estimates. NFPA12 (2012) standard formulas have been applied. The manufacturer is not responsible for sizing. The actual sizing is the responsibility of the customer.

The parts below are available as standard. Other sizes and temperatures are available upon request.

AMFE | ||

|---|---|---|

Part | Name | Description |

10899 | AMFE SR3 68 | AMFE with JOB 68°C / 155°F bulb |

10900 | AMFE SR3 79 | AMFE with JOB 79°C / 175°F bulb |

10901 | AMFE SR3 93 | AMFE with JOB 93°C / 200°F bulb |

S-AMFE | ||

|---|---|---|

Part | Name | Description |

11043 | S-AMFE SR3 68 | AMFE with JOB 68°C / 155°F bulb and sensor connection |

11044 | S-AMFE SR3 79 | AMFE with JOB 79°C / 175°F bulb and sensor connection |

11045 | S-AMFE SR3 93 | AMFE with JOB 93°C / 200°F bulb and sensor connection |

AMFE and S-AMFE are also available in stainless design.

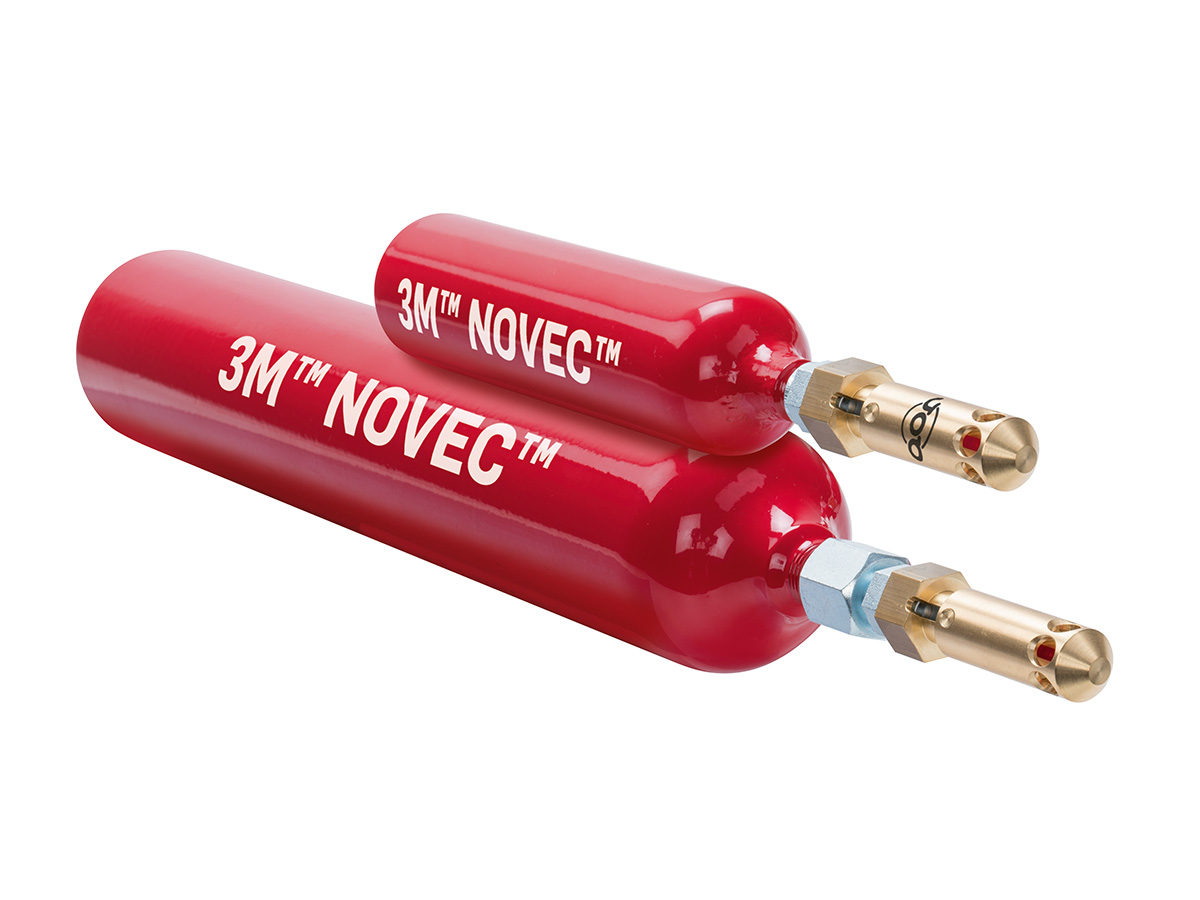

3M NOVEC cylinders | ||

|---|---|---|

Size | Part | Name |

#0 | 11100 | Cylinder NOVEC 26 ml |

#1 | 11101 | Cylinder NOVEC 72 ml |

#2 | 11102 | Cylinder NOVEC 120 ml |

#3 | 11103 | Cylinder NOVEC 241 ml |

#4 | 11104 | Cylinder NOVEC 360 ml |

#5 | 11105 | Cylinder NOVEC 603 ml |

CO2 cylinders | ||

|---|---|---|

Size | Part | Name |

#0 | n. a. | n. a. |

#1 | 10945 | CO2 35g / 100°C |

#2 | 10946 | CO2 60g / 100°C |

#3 | 10947 | CO2 135g / 100°C |

#4 | 10948 | CO2 200g / 100°C |

#5 | 10949 | CO2 350g / 100°C |

CERTIFICATION

AMFE series by JOB is produced in Ahrensburg, Germany, following all applicable standards. The AMFE also is RoHS conform (and confirms to the EU 2002/95/EC standard).

The manufacturer of AMFE products is JOB - the leading brand in fire detection that stands for uncompromised quality. JOB complies with ISO 9001, ISO 14001 and carries other relevant certifications from organizations around the globe.

Extra information on the certification of each of the AMFE components is available here:

AMFE.pro > INFO > CERTIFICATION

MARKING / TRACEABILITY

Each AMFE is marked with a label which, in addition to the type designation and activation temperature, shows the JOB part number and a unique batch number. This batch number guarantees a 100% traceability of all components being used for the product.

Thus, not only information about the components being used can be retrieved, but also details about all executed quality tests during the production process. In addition, the extinguishing agent cylinders also carry a unique serial number, which allows full traceability.